My Blog

Low Temperature Differential Stirling Engine: Conclusion

I had a blast making the Stirling Engine! In fact, I learned how to use a lathe to make this engine.

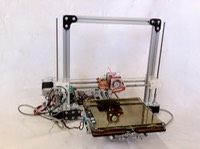

In making this project, in addition to a lathe, I used a drill press, lasercutter, hot-wire foam cutter, hole tap, mitre saw, sabre saw, (lots of) sandpaper, bolt-cutters, and a hand drill. I followed James R. Senft’s design and measurements and started with raw materials (pictured above.) Below is a video of the engine working off of the heat of a coffee cup. I would recommend this project to anyone looking to improve their machining skills!

…Low Temperature Differential Stirling Engine: Troubleshooting

At first, the engine did not work. Instead of becoming discouraged, I began to troubleshoot. Senft’s book warns of a couple things: friction and lack of air-tight seals. If there is too much friction, the engine could lose too much energy and stop. If the chamber is not sealed, then air could be released and the engine will not be able to go through air cycles and not be able to run.

First, I checked all the bearings and possible sources of excess friction, but these did not seem to be an issue.

…