Between the two plates sits the displacer ring, made of clear acrylic plastic. The displacer ring forms the walls of the displacer chamber, within which air is heated and cooled and the displacer block moves.

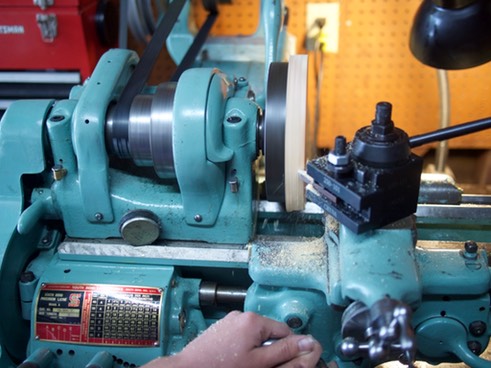

To make the ring, I started with a long tube of acrylic from which I chopped a ring on the mitre saw. Next, using a mitre, I cut a circle of wood with a rough outer diameter, nearly the same size as the inner diameter of the tube. This will eventually act as an arbor on which I attach the ring to the lathe head:

I attached this circle to a lathe plate and shaved down the edge of the circle so it would fit snugly inside of the ring.

I fit the ring over the wooden arbor and cleaned up the sides to the proper width.

Next, I cut an indent into the inside of the ring for a rubber rope that insulates the chamber. Note: later I determined that this insulation was leaking. Instead of cutting the indent, I just attached flat insulation on the base of the ring. I found this method creates a better seal.

The ring was now finished!